VF Outlet Achieves over 25% Savings with GridPoint’s Energy Management Solution

BUSINESS SITUATION

VF Corporation, the $12 billion apparel, and footwear giant has long been dedicated to minimizing its carbon footprint and environmental impact. In 2012, the company established corporate-wide energy reduction and sustainability goals across its multiple brands and subsidiaries. Responding to the corporate initiative, VF Outlet sought an energy solution to enhance facility maintenance operations, combat rising energy costs and continually drive energy savings year over year. After considering several options, VF Outlet identified GridPoint’s Energy Management Solution (EMS) as the most comprehensive approach to fulfill their needs. The GridPoint system was installed shortly thereafter at 4 pilot locations.

Noticing immediate results, GridPoint’s EMS was extended to an additional 21 stores over the following 2 years. During that period, VF Outlet’s savings across the fleet averaged over 25%, with individual locations capturing nearly 30% in energy savings. Overall, the entire fleet vastly outperformed expectations, realizing better than a 20 month payback period.

SOLUTION

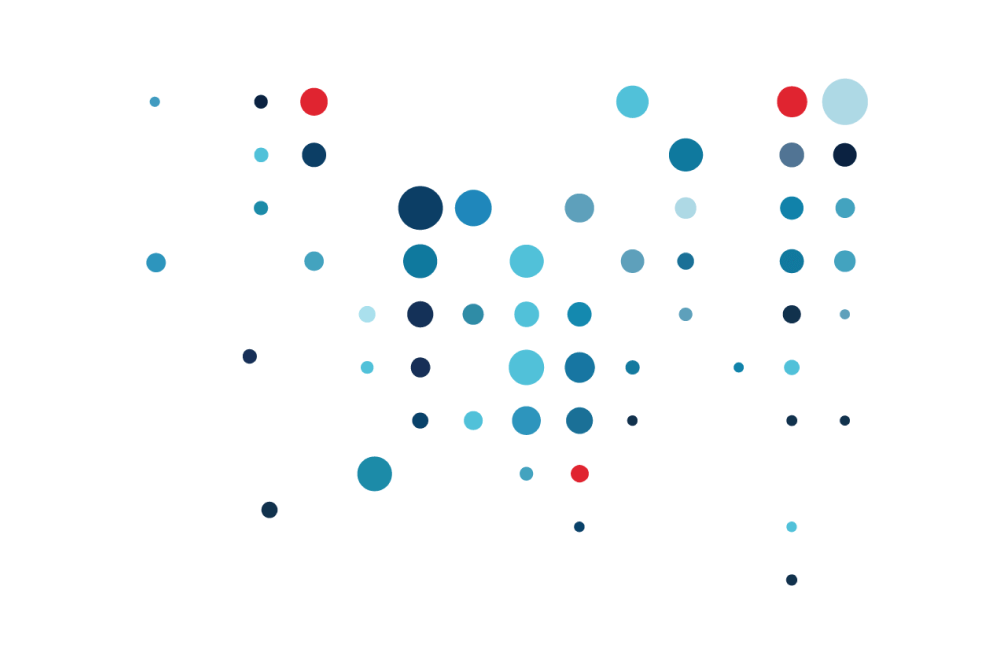

GridPoint’s solution for VF Outlet utilizes submetering and monitoring devices to collect real-time, granular energy data at the asset-level while additionally implementing HVAC and lighting controls. GridPoint’s cloud-based software platform, GridPoint Energy Manager, then aggregates that data and applies big data analytics to provide valuable tools such as alarms, equipment and site diagnostics, sustainability management, project financial metrics tracking and more. Energy Advisory Services (EAS) and Control Support Services (CSS) complete the solution facilitating energy-saving projects and offering 24/7 site support.

RESULTS

By installing GridPoint’s comprehensive EMS at their sites, VF Outlet gained access to real-time, granular data. This data has empowered them to set corporate policies designed to increase energy savings and avoid peak kW utility charges, diagnose malfunctioning equipment, verify equipment maintenance repairs and predict when costly equipment will need to be replaced. By aggressively regulating facility controls and maintenance operations, the company has taken strides to support corporate sustainability efforts and lessen their carbon footprint while benefiting from over 25% energy savings across sites. Beyond these core savings, the sophisticated approach taken to reduce energy spend by the EAS team has identified an additional wealth of savings opportunities and will continue to uncover more opportunities in the future.